Wolfe Ridge Welding and Metal Fabrication

Wolfe Ridge Metal Fabrication offers custom welding and metal fabrication services. We possess the capability to manufacture complex, multi-part, custom-engineered assemblies.

Our depth of knowledge, experienced staff, and modern equipment bring an unmatched level of quality to each project Wolfe Ridge Metal Fab produces. We work with a variety of materials including carbon steel, stainless steel & aluminum in tubing, sheet, or plate form. Our capabilities include grinding, sanding, bead blasting, bending, sawing, laser cutting, deburring & welding.

Our welders have extensive experience in Shielded Metal Arc Welding (SMAW) Stick Welding, Metal Inert Gas (MIG) Welding and Tungsten Inert Gas (TIG) arc welding.

Contact us today to learn how we can help with your next custom welding & fabrication application.

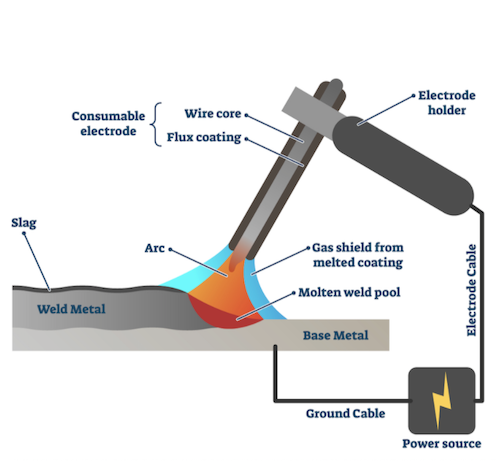

Shielded Metal Arc Welding (SMAW) or Stick Welding

Shielded Metal Arc Welding (SMAW) or Stick Welding

Shielded Metal Arc Welding (SMAW), also referred to as “stick welding,” is the most commonly used of the various arc welding methods (arc welding is a process using electricity to create enough heat to melt and join metals). This welding process uses a constant alternating current (AC) or direct current (DC) that flows through a flux-coated electrode to create an arc between the electrode and the metals to be joined. As the arc is created, the workpiece base metal and electrode metal melt together, forming a weld pool. The flux on the electrode decomposes as the electrode melts, shielding the arc. This flux prevents the weld from oxidizing with the surrounding air.

Key advantages and limitations of this arc welding process include:

Advantages:

- Due to it being the most commonly used form of arc welding methods, welders and equipment are readily available.

- The equipment is relatively inexpensive and the level of training required is lower than other forms of welding processes.

- Since the arc is shielded by flux coated on the electrode, SMAW is a great process in outdoor/high wind environments where shielding gas could blow away.

Limitations:

- SMAW produces slag on the weld that must be removed after every weld pass, at stops and starts, and before starting a new weld bead.

- Deposition rates (amount of filler metal that can be deposited expressed in pounds per hour) are lower than other processes such as GMAW.

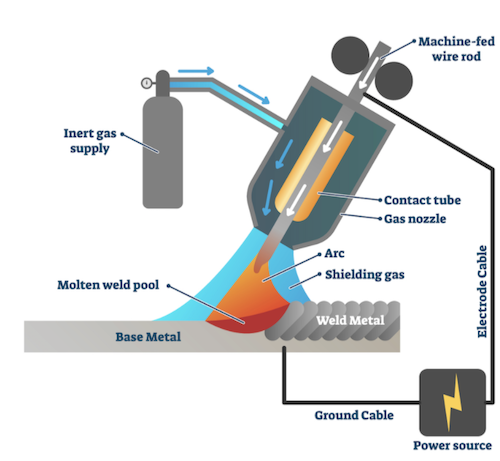

Gas Metal Arc Welding (GMAW) or MIG Welding

Gas Metal Arc Welding (GMAW) or MIG Welding

Gas Metal Arc Welding (GMAW), also referred to as “MIG welding,” is an arc welding method that uses a thin wire fed from a spool inside the welder as an electrode. The wire flows from the spool through a tube, into a wire guide, and out the end of the welding torch. The welding torch has a trigger on it, and when activated the wire is continuously fed, the arc is struck, and argon shielding gas is released around the arc, all occurring simultaneously. The wire acts as filler metal in GMAW, so it is a consumable electrode.

Key advantages and limitations of this arc welding process include:

Advantages:

- GMAW is fairly simple to operate due to the fact that the trigger activates all three crucial steps of the welding process: arc, gas, and filler metal.

- The deposition rate is very high due to wire feeding.

- The shielding gas prevents slag, which allows for minimal post weld cleaning.

- GMAW works with most commercial metals and alloys.

Limitations:

- GMAW welding equipment is more complex, more costly, and less portable than SMAW welding equipment.

- Due to the shielding gas coming out from the nozzle, welding in high draft areas is difficult.

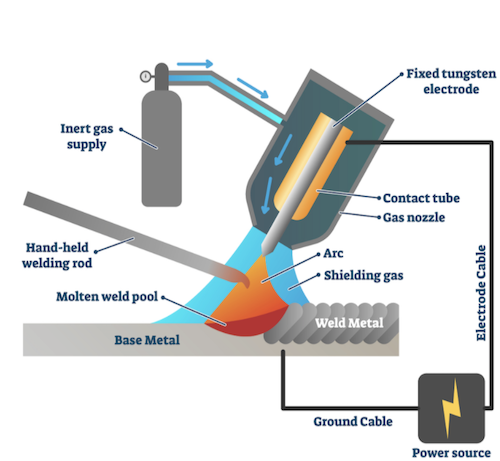

Gas Tungsten Arc Welding (GTAW) or TIG Welding

Gas Tungsten Arc Welding (GTAW), also referred to as Tungsten Inert Gas (TIG) Welding, is an arc welding method that uses a non-consumable tungsten electrode and can be used with or without the addition of a filler metal. If a filler is used, a long rod is fed into the weld pool by the welder’s non-torch hand.

GTAW uses a constant AC or DC power supply. DC is typically performed with the electrode negatively charged and the workpiece being positively charged, which is known as direct current electrode negative (DCEN) polarity. DCEN welding offers deeper penetration and increased welding speeds. AC provides cathodic cleaning that removes oxides from the workpiece’s surface, which occurs during the portion of the AC wave when the electrode is positive. This effect is necessary when welding nonferrous materials such as aluminum or magnesium.

Key advantages and limitations of this arc welding process include:

Advantages:

- When done properly, GTAW produces high purity welds that are generally clean and free from defects. As a result, this method r equires little post-weld cleaning.

- GTAW is useful for small fabrication due to it having excellent control of root pass weld penetration.

- GTAW can be used without any filler metal, depending on the workpiece, and is useful when welding nonferrous materials.

Limitations:

- GTAW has a very slow deposition rate and a low tolerance for dirty electrodes or contaminants on filler or base metals.

- Highly skilled welders are required due to the complicated technique involved with this process.

- Welding outdoors or in areas of high air turbulence can be difficult.

Gas Tungsten Arc Welding (GTAW) or TIG Welding

Welding Materials

Different types of metals respond differently to welding heat. Each has a different melting point, tensile strength, and level of ductility. A welder must understand the properties and limitations of the material prior to welding in order to get the best results possible.

Wolfe Ridge Metal Fabrication specializes in welding the following types of metal:

Carbon Steel

- Carbon steel. Carbon steel includes a broad range of steel subtypes with different elemental compositions. The percentage of carbon present in the compound determines how the metal will react to the welding process. Low-carbon mild steel is one of the most weldable metal materials available, since it possesses few elements that might interfere with the quality of the weld.

- Stainless steel. Stainless steel contains chromium, which imparts the material’s prized heat resistance but also acts as a heat sink. The stainless steel medium retains heat, making speed and precision necessary to prevent warping or scratching the surface. Depending on the project and precision required, stainless steel works with both MIG and TIG welding.

- Aluminum. Aluminum is much less susceptible to corrosion and lighter in weight than other materials. Aluminum conducts heat more easily than the other metals and melts at a much lower temperature. TIG welding is typically preferred for aluminum welding, though MIG welding can be used in some situations.

Quality Welding Services Through Wolfe Ridge Fabrication in Eau Claire Wisconsin

Wolfe Ridge Fabrication has years of experience in welding and metal fabrication. Our welders work with a variety of mediums using the latest in welding techniques and equipment. We look forward to working with you on your custom fabrication design. To see how our welding capabilities can support your needs, please request a quote or contact us today!